17 1 what are the differences between bulk deformation processes and sheet metal processes.

Difference between bulk deformation and sheet metal process.

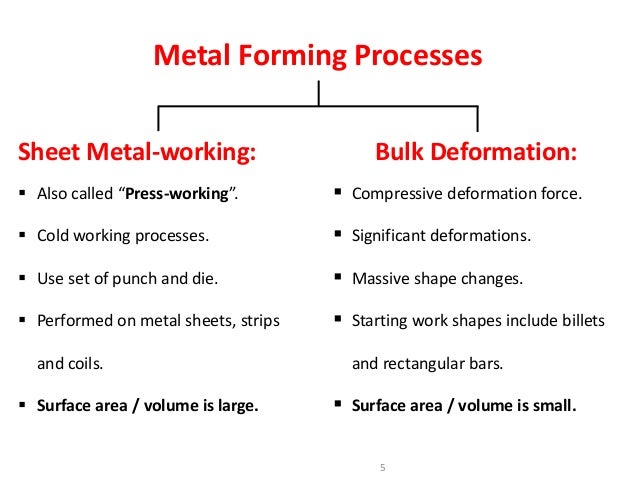

In bulk deformation the work parts have a low area to volume ratio whereas in sheet metalworking the area to volume ratio is high.

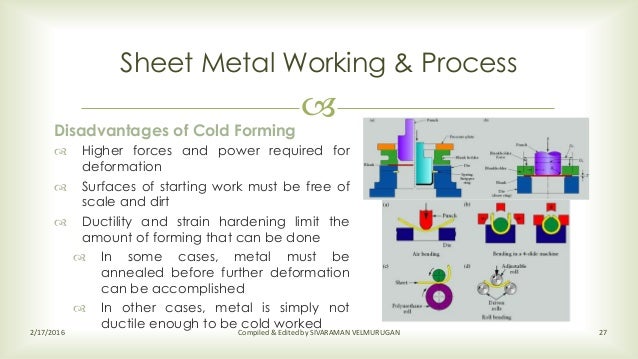

The term is used because most sheet metal operations are performed on presses.

Chapter 18 review questions and problem answers review questions 18 1 what are the differences between bulk deformation processes and sheet metal processes.

In bulk deformation the shape changes are significant and the work parts have a low area to volume ratio.

Answer in bulk deformation the shape changes are significant and the workparts have a low area to volume ratio.

In sheet metal processes the area to volume ratio is high.

What are the differences between bulk deformation processes and sheet metal processes.

18 2 extrusion is a fundamental shaping process.

The key difference between bulk deformation and sheet metal forming is that in bulk deformation the work parts have a low area to volume ratio whereas in sheet metal forming the area to volume ratio is high.

I what are the differences between bulk deformation processes and sheet metal from mecha 000 at mfi technological institute.

In sheet metal processes the area to volume ratio is high.

0 0 0 votes log in to add comment.

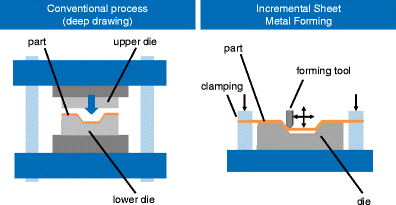

Bulk causes workpiece to deform plastically pushed to fill die sheet metal is on workpiece of sheets or strips pushed into a die 17 2 extrusion is a fundamental shaping process.

Extrusion is a fundamental shaping process.

What are the differences between bulk deformati.

Bulk causes workpiece to deform plastically pushed to fill die sheet metal is on workpiece of sheets or strips pushed into a die.

Why is the term pressworking often used for sheet metal processes.